Guidebook: Printing Dissertations

When a dissertation is nearly completed, the great questions of printing occur. Often combined with a irritatingly definite period.

At this very point this little guidebook is supposed to join in and help, it contains a cross section of dialogues we've had with our customers throughout the years, so it contains answers to the customarily asked questions.

- Printing

- B/w and Colour Print

- Single- or Both-sided Printing

- File Format pdf

- Page Adjustment

- Landscape formatted pages

- Blank Pages

- Paper

- Binding

- CDs

- Ordering Online ( Technical help in using the online shop is provided in the shop guide. )

- Production

- Upon Completion

Printing

B/w and Colour Print

Colour and b/w pages are automatically recognized by our printing systems.

Our filecheck displays amount and number of counted coloured pages in a template file.

This file check also provides information about the pages of the recognized colour prints, this makes also editing much easier.

Since coloured prints are clearly more expensive than b/w prints, sometimes it is thought a bit longer about having some pages containing pigment printed black and white.

This is done very easily by switching to complete b/w mode, maybe with a coloured title page only. However, if this is also considered for enclosed pages, it is absolutely recommended to convert these pages into greyscale already in the original file. Mostly concerned are included graphics, converting the colour depth to grey scale via 'edit' function of every customary graphical software will do. This applies particularly for scans, they often contain pigments invisible to the naked eye.

Of course it is also possible to deliver the corresponding page numbers (always use the internal page number at the lower screen of the pdf-file, not the paging of the document, please) requesting rededication, but at this point usually so much extra handling time is needed that this marginalises the cost saving. To make things worse, it is no longer possible to print by the pile, which has a negative effect on the concision of the resulting print sets.

Colour fidelity

Since monitors intensify colours through their luminance, it is recommended to generate pastel tones, especially those with grey tint, a little more intensively than they are desired in printing.

Monitors illuminate graphics from the back, so colours on the monitor will always appear somewhat brighter than on paper, especially with darker colour tones, this should be noted and a sample print should be made if necessary.

Single- or Both-sided Printing

Sometimes already external forces like the capacity of the chosen binding type or requirements of the examination authority lead to both-sided printing.A further consideration might be the price of 100g or 120g paper, though paper usually has a weak effect on the total.

Single-sided printing ist standard, we don't have an explanation for this, maybe the reason can be found in the following paragraph.

Both-sided Printing

If you want to choose both-sided printing, you should mention that already from the start. Most word-processing programs offer this mode already at document setup and thereby decrease author's worries, a subsequent modification usually doesn't run without loss.

Of particular importance is the right-placed paging, this is simplified by page numbers positioned in the center.

The predetermined margin left blank always has to be placed on the right side.

File Format pdf

Printing is carried out exclusively from pdf files.

This file type is the only platform independent one. Files saved in other formats contain conversion failures too often. The more grateful appearances of such failures are files that can't even be opened or that contain only hieroglyphics, but mostly failures hide in bits and bobs that aren't recognized in a hasty checking.

If all else fails, we sometimes make an exception, but reluctantly. The risk in such a case is transmitted to the customer though.

Please bring time and your own application development system then.

In case you have problems with converting, assembling or sorting, you can resort to other converters than the one that is integrated in your developing application. These converters install themselves as program independent print drivers on your system. We place a very extensive and reliable pdf converter for PCs at your disposal, others can be found on the Internet.

Page Adjustment

Our standard is printing with page adjustment.

Background: Printing always spares a framing blank margin of a few millimeters. Printing without page adjustment could cause cropped elements near this edge.

Using page adjustment the page is scaled down to about 97% before printing, so content is complete extant at any rate.

In case printing without page adjustment should be necessary, please inform us.

In case printing without page adjustment should be necessary, please inform us.

Marginless printing is not possible, not on any laser printer of this world, because toner powder would always overshoot the edge and into the machine and thus damage it.

One could print on DIN A3 and cut, but a cut that's 100% straight and aligned to the other sheets is equivalent to an art form and then still carries the risk that still half a millimeter of white edge remains somewhere, in short: That would be flub and therefore nothing for us, marginless printing is a matter for an offset printer.

Landscape formatted pages

If individual pages are created in the landscape format, our print drivers automatically convert the print so that it is rotated by 90° and the entire space on the sheet is used, with the side header on the binding side.

Blank Pages

Especially in case of both-sided, but also of one-sided printing applies: If a page is to be left blank (often necessary in both-sided printing in order to let the next chapter start on the right), it has to be an integrated blank page in the document. Usually there's an extra function for preventing paging of these pages.Blank pages are recognized as such by our printing systems and not charged.

Paper

Standard in dissertation printing is a coated 100g paper. Coating compacts the surface in order to gain a very fine and clear print image, worth considering especially concerning graphics.

Printing without graphics can also get along with our 80g paper Double A, which due to its high fibre density haptically hardly differs from 100g paper. Also the degree of whiteness is nearly identical. Since the surface isn't coated accessorily, prints fray a little bit more, which is less noticeable on font than on graphics.

120g paper is the Ferrari among document printing paper, something impressing. In order to guarantee an optimal print image, the surface is coated, similar to 100g paper, but thanks to the 1.2-fold thickness it seems even whiter. The 100g paper is opaque too, but if you test one of it lying on another plain and another one on a printed sheet, the one on the printed sheet (or one with a printed back side) will seem a bit greyish. This effect is avoided with 120g paper.

It also differs from the other paper haptically, it is that heavyweight, customers sometimes test whether they have possibly caught two sheets.

120g paper is already too stiff for usage in glued bonds, on browsing the pressure among adjoining sheets is so high they'd like to escape, so they tend to detach themselves from the glue in the spine.

Paper in excess of 130g is not advisable for the purpose of printing books, heavier paper gets in the range of cardboard.

Recycled Paper

In order to decrease the ecological footprint we offer two types of uncoated 80g recycled paper with the ecolabel 'Blue Angel':

- Classic recycled paper without bleach, suitable for private use or just to keep conscience really clear

- Pure white recycled paper with bleach as an alternative to 80g paper Double A

For a certification with the Blue Angel at least 65% waste paper of the lower and middle category has to be used. The more inked the waste paper, the lower its category. For this reason, in these recycled papers smallest particles can be found of which the previous colour could not be fully removed. (Until now, in all these years no-one has ever mentioned this to us.)

The ageing resistance of recycled paper is equal to the ageing resistance of fresh fibre paper.

Format DIN A3

If your template contains pages formatted in DIN A3, the printer driver only detects a landscape format, therefore it is absolutely essential to pass this information on to us during the ordering process and to specify the corresponding pdf page numbers.

A3 formats are folded zigzag, so after printing and before binding we fold the sheet in its center and then again justified to the right border, so finally the right half of the left half of the sheet is covered.

Please consider the binding margin required on the left side.

The additional effort is charged as extra services.

Binding

Amount of Pages

Sometimes the type of binding is already determined by available capacities:|

up to 125 sheets / 250 pages both-sided on 80- oder 100g paper |

hardcover, softcover, glued bond, spiral |

|

up to 105 sheets / 210 pages both-sided on 120g paper |

|

|

up to 250 sheets / 500 pages both-sided on 80g or 100g paper |

hardcover, glued bond, spiral |

|

up to 210 sheets / 420 pages both-sided on 120g paper |

|

|

up to 270 sheets / 540 pages both-sided on 80g or 100g paper |

hardcover, glued bond |

|

up to 225 sheets / 450 pages both-sided on 120g paper |

|

|

up to 280 sheets / 560 pages both-sided on 80g or 100g paper |

glued bond |

If the amount of pages lies just slightly over limitation and single-sided printing is favoured, it is worth considering minimizing the amount of sheets by printing only particular parts in both-sided mode.

Durability

Since our paper is wood-free and laser prints are everlasting, it depends primarily on the type of binding whether a dissertation delights over the years.The most durable type of binding by far is of course the hardcover, only direct solar irradiation can cause damage to its colour, in other respects this type of binding is nearly indestructible. We compress several times, so the sheets lying in the steel rail are stuck to each other maximally.

The cover itself is slightly oversized, this helps protecting the sheets and avoids signs of wear.

The cover itself is slightly oversized, this helps protecting the sheets and avoids signs of wear.All of these benefits are also provided by the softcover, but the cover is flexible, therefore much thinner and therefore more vulnerable. The front is made up of plastic foil, this can dry out and get fracturable over time.

The most fugacious of the offered binding types is the glued bond. The reason for this is on the one hand the nature of things, glue is just less durable than mechanic procedures, on the other hand the flexibility, the strap on the spine consists of fabric and glue, this keeps sheets together indeed, but it can't resist higher strain, even less being treated improper (and examinants too take the bait of leveling opened books with their thenar much too often).

The stability of glued bonds decreases with increasing binding size.

If glued bond isn't prescribed, it is absolutely recommended to think about the softcover as an alternative.

More practical than durable is the metallic spiral, this binding is also more affected by the bound paper than the other way round, so if paper warps over time, the spiral will deform. However, use can hardly cause damage to this type of binding.

Front Foil

Front foils are offered in glossy or frosted style. Matt foils seem like sand-blasted. Glossy foils are standard, but the matt ones are more convenient. Damages and signs of wear are much less conspicuous on matt foil.Matt foils are contact-transparent, which means they look a bit milky, but when they touch the print lying behind they show every detail of it.

Front Paperboard

In case of glued bonds and spiral bindings, paperboard can also be chosen as front instead of a foil, additionally it can be embossed or printed.

If the front paperboard is printed, the front carton becomes the front page, the back of the paperboard remains blank (if you want this differently, please let us know). Page 1 of the file template is printed onto the cover and the inner part starts on the right side with page 2 of the file template, in one-sided as well as in both-sided printing. If you want to customise your template file concerning this matter and e.g. duplicate page 1, the PDF24-Creator helps.

Only unstructured / smooth paperboard is suitable for printing and only structured paperboard is suitable for embossing.

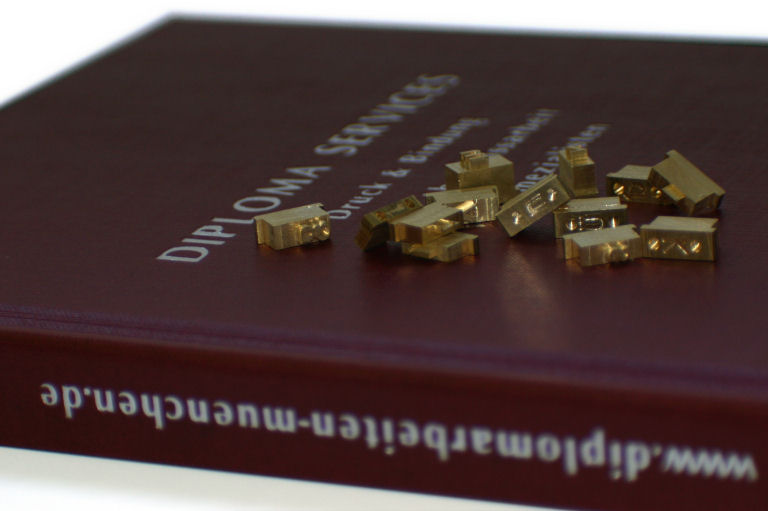

Embossing

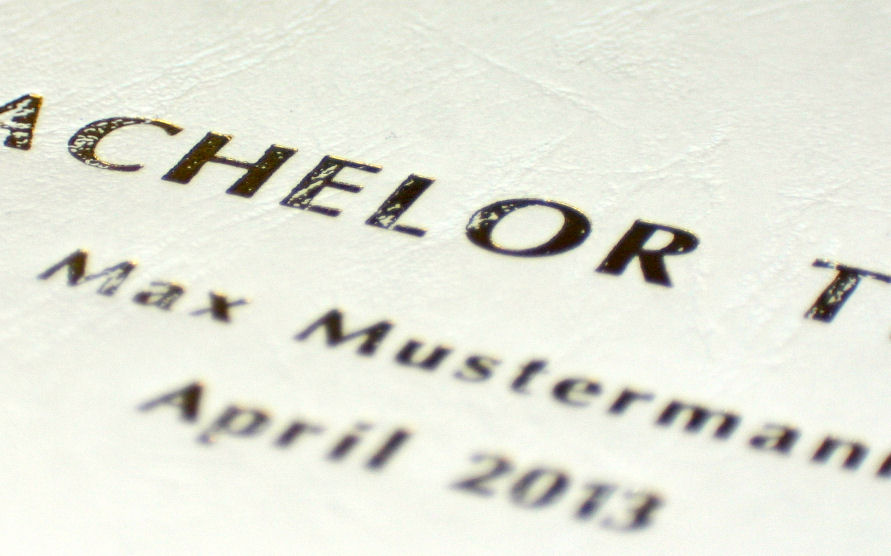

Embossing is always a wise decision as far as upgrading is concerned, combined with a hardcover already in order to avoid a downgrading: If an examinant can't distinguish front from back, perhaps even opens it on the wrong side, easily a diffuse feeling of "Someone saved money in the wrong place" occurs. The lettering of embossed covers is generated of single characters casted in metal blocks. These metal blocks are greatly heated and then burned into the cover.

The lettering of embossed covers is generated of single characters casted in metal blocks. These metal blocks are greatly heated and then burned into the cover.Because these blocks are only delivered in standard character sets, graphics or all too special characters can't be embossed.

You have the opportunity to test various letterings in our schematic hardcover configuration, varying character amplitudes are already considered.

You have the opportunity to test various letterings in our schematic hardcover configuration, varying character amplitudes are already considered. If textured, especially leather textured, paperboard shall be embossed, you have to consider that embossing takes place on just one level, thus on spots where texture is worked in very deeply remains a fine gap in the embossing, it doesn't become illegible though. It's a matter of taste, some find it stylish, for others it looks like a blemish.

If textured, especially leather textured, paperboard shall be embossed, you have to consider that embossing takes place on just one level, thus on spots where texture is worked in very deeply remains a fine gap in the embossing, it doesn't become illegible though. It's a matter of taste, some find it stylish, for others it looks like a blemish.

Hardcovers can also be embossed on the spine, but only with a binding capacity of at least 60 sheets of standard paper, because beneath this capacity the minimal character height of 6 mms isn't reached. In case a spine embossing is indispensable, special feeder stripes can be used to fill the gap, but this doesn't altogether beautify or stabilise the binding. And with 40 sheets or less, there's no spine embossing available at all.

Hardcovers can also be embossed on the spine, but only with a binding capacity of at least 60 sheets of standard paper, because beneath this capacity the minimal character height of 6 mms isn't reached. In case a spine embossing is indispensable, special feeder stripes can be used to fill the gap, but this doesn't altogether beautify or stabilise the binding. And with 40 sheets or less, there's no spine embossing available at all.The additional effort is charged as extra services.

Including a spine embossing a hardcover no longer consists of just one framed cover but of three assembled pieces. This is not recognizable at first sight, only at examining the junctions viewed from the flat side.

Including a spine embossing a hardcover no longer consists of just one framed cover but of three assembled pieces. This is not recognizable at first sight, only at examining the junctions viewed from the flat side.

Why we don't offer a cover print from file for hardcovers:

Because of our demands on quality. The currently best labelling machine is made in China and simply doesn't offer what we could sell in good conscience - certainly not at the price we'd have to demand for it. The applied colour runs into each structure and as soon as the lines become a little bit finer, they are badly or no longer represented.

Once a machine is on the market that can offer a decent quality, it is ours.

Hardcover Cream vs. DHL Shipping

These two don't get along very well. Anyway, we no longer dare. DHLs way of dealing with parcels is not compatible with the steel rails of hardcovers cream, the prints sometimes don't fit anymore after shipping. So far, this has only happened with one order sent several times, but that's enough, we want hardcovers to be delivered in the best possible way.

Hardcovers cream have a name supplement on the side of their package all the other hardcovers do not have, maybe it's because the metal is softer, we have no idea, but we simply don't dare to entrust this hardcover to DHL.

It should be pointed out explicitly that hardcovers cream do an absolutely good job in daily use and also under strain (we have tested a lot), nobody has to be afraid of buying lower quality with this colour.

CDs

At fabrication the pdf template, which has also been printed, is burnt on a blank CD and the outcome is controlled.

The file is not renamed, sometimes you wish that this would have been taken into account when naming.

In case a further version in another file format is desired, it is no problem to have that done. However, if whole folders, graphic collections or similar are to be burnt, we must carge the additional effort for checking the success of the burning process as extra services. Alternatively, the blank can also remain empty so that it can be burned at home.

Blank CDs are covered with a white label, which is inscribed on demand. Further design options such as graphics or coloured accentuations are not available.

For inscription three blocks are available, one in boldface on the upper half and two more on the lower one. In this process font size and text length are automatically adjusted. So theoretically the text could be of any length, practically font becomes unreadable at about 150 characters per block.

Inscriptions can be tested via preview in the online shop.

Ordering Online

Payment

Online orders can be payed cash or by ec when picking up or via PayPal or advance payment in case of delivery.

If delivery is combined with advance payment, the date of delivery of course corresponds to the transfer term.

Delivery by Courier

Within the city of Munich delivery by courier takes place within a few hours. Which postal code can be supplied can be found in the price list by clicking on the delivery zones.

Because delivery is transfered to second-party providers, it is not suitable for time-sensitive orders. We can only guarantee the two hours fabrication time, but we don't have any influence on the dates of pick up or delivery.

Presently deliveries pass off within two to three hours after finalization.

DHL Shipping

For delivery adresses out of (and of course also within) the city of Munich you have also the option of authorising DHL with delivery. Provided are Standard and Express shipping.

This service accured from the Corona shutdown, we adhere to it because of the request of many customers, but we explicitly allude to not assuming liability for potential contract violations on the part of the shipping service provider. DHL does not give any guarantees even at Express about the delivery time. For example, if an Express package doesn't come until the day after next, this has no effect on anything, you don't even get the express surcharge back. Needs to be considered.

Express delivery had been suspended when the cut-off date was antedated from 6 to 1 pm. This term extension and the absence of any guarantees are actually disproportionate to the prices and benefits for our customers.

In the second half of 2023, however, DHL has considered itself increasing the Standard delivery term by one day, and now DHLExpress is making more sense again, so we chose to offer it again. The problem that parcels are picked up only once a day at noon remains, so we had to pre-lay the deadline for dispatch on the same day to 10 am. In addition, we have to travel through half the city for handing over Express parcels and stand in line, so we had to launch a minimum order value for Express shipping.

Since all of this doesn't please us either, we'd always prefer pick up or delivery by courier.

Production

Period

Our guaranteed period of production amounts two hours starting on order receipt. This period contains all imponderabilities and tolerances on our part, therefore the guarantee. Not contained are delays as waiting periods, advisory services or sample copies, the two hours start when the order is placed / when the fabrication can start.

In particular cases it is possible that production passes off faster or is downgraded in the first place. In particular cases.

If a friend reported such an event to you without mentioning that this was an exception, you can be sure: We did mention it to him.

Because our production hours are located outside our opening hours, the indicated period of two hours refers not just to the opening hours, but to the hours of production. For example it is possible to place an order in the evening and pick it up at 10 pm the next day.

Cancellation

Since printing is done by machines, this part is usually initiated immediately after receipt of order, often even for orders whose completion date is still quite far in the future.Now the print stacks lay and wait for further processing, this is the time in which single pages can be swapped or bindings modified or cancelled completely.

Ergo: A complete order cancellation is only possible during the very first minutes, modifications perhaps even within an hour.

Orders with further away pick-up date are usually completed after four to five hours and then cannot be cancelled anymore.

Upon Completion

Replacing Pages

In case a slipped-in mistake is mentioned after production and single pages have to be replaced, this is possible once with soft- or hardcovers. Once, because binding quality is adversely and considerably affected at second time, sometimes even the cover. Hardcovers with spine embossing and less than 60 sheets can't be bound twice at all.This kind of replacement doesn't cause material costs, but expenses of reworking have to be charged. If the cover shouldn't be usable anymore, the content (except for outer sheets) can still be saved, so that binding costs accrue, but no further costs for printing or paper.

In case of metallic spirals, the spiral has to be unfixed, expenses are incurred for a new binding and the additional work.

No replacement is possible in case of glued bonds, they have to be manufactured a second time.

Waved Paper

If bonded paper develops waves subsequently, it has become damp (which happens easily to a hygroscopic material like paper, therefore we deliver in cardboard boxes and paper bags).Relief: Take the material into the bathroom while showering, afterwards weight it down evenly and intensely, then let it dry thoroughly in an arid environment at room temperature(!).